Frequently Asked Questions

Got a question?

We encourage you to browse our FAQs before making your Vitripiazza purchase.

Can't see your question?

Contact Us-

Through Full-Bodied The body of the tile colour is consistent with the raw materials used in the manufacturing. This body type is referred to as a “salt & pepper finish”. The tile has no surface print, and the colour of raw materials run all the way through the tile. In this type of tile, the colour options are limited but if chipping does occur then it is normally not so visible to the naked eye.

Body Information:

- No digital printing on the upper side of the product, only a salt & pepper body.

- Body colour denotes on the top surface finish.

- In this type of porcelain, there is a very limited amount of colour options available.

Colour-Bodied The body of the tile is matched to one similar to the surface print, though once laid as paving this is immaterial. There is little visible difference if there are small chips caused by accidental damage during cutting, handling and install. Keep in mind that porcelain is an extremely dense material, so the chances of chipping are very low. They still go through the same vitrification process, assuring the user of very low water absorbency, high stain resistance and long-term durability.

Body Information:

- Colour match to the surface colour which is visible through the entire product.

- Little visible difference if there are small chips.

- Can still have various finishes such as polished, slip resistant, matte.

-

Rectified Tiles have their edges machine cut after firing, giving a consistent size with 90 degree angles allowing for minimal joint widths and crisp lines.

Body Information:

- Precisely ground and machined

- Near-perfect straight edges

- Exact dimensions with small manufacturing tolerance, normally +/-1mm

- Tighter joints are achievable from 5mm and above

Non-rectified Tiles have uneven edges, giving them a more natural look, but with the downside of needing more grout to install. Whilst the edges are not machined, the edges are still straight due to the high-quality moulds used on the press.

Body Information:

- Can have slight dimensional differences

- Will have a bigger manufacturing tolerance than rectified

- Larger joint widths are recommended, normally from 7mm and above

-

What are glazed porcelain paving tiles?

A glazed porcelain tile has a protective coating of liquid glass applied to its surface, giving them a shiny, non-porous surface. These types of porcelain paving can be coloured and printed with a wide variety of designs. They are more suitable to be used internally.

-

Porcelain paving is known to be one of the easiest types of flagstones to keep looking clean and 'as new'.

Its fantastic technical properties mean it doesn’t weather as quickly as other paving types and when it does need a general clean, it’s requires minimal effort. Vitripiazza is an extremely strong, hard wearing paving type and has a very low water absorption, giving excellent resistance to the environment and weather, with a high resistance to UV, frost, salt and acid.

For further information see our Guide to Understanding Vitripiazza.

-

What gives porcelain such superior properties including stain resistance is the fact that the paving is non-porous. Because of this low porosity, the porcelain requires a priming slurry to be applied to the underside of the flagstone, before being laid onto the mortar bed, to create an exceptional bond between the two. Our Pavetuf range offers a Priming Slurry designed for this.

-

There are various methods for the installation of vitrified porcelain paving. Our Guide to Planning & Installing Vitripiazza has been created with our suggested installation process which will give the very best aesthetic results and assure you of the short, medium and long-term performance of the paving in the UK climate.

While it’s true that you can lay directly onto grass or sand, we would strongly recommend you install on the construction shown within this guide.

-

There are various jointing options available for vitrified porcelain and the key to a successful joint is choosing the correct type of solution for your application. See our recommendations below:

Pavetuf Jointing Grout – Specifically designed for use with porcelain products and is the ideal choice for professionals and DIY’ers. Suitable for joint widths of 3mm to 15mm, at full depth of the tile. Suitable for driveway and pedestrian use. Internal or external use. Smooth finish.

Pavetuf Jointing Mortar – Can be used for any type of paving. Suitable for joint widths of 5mm to 50mm, with minimum 20mm depth required. Suitable for driveway and pedestrian use. External use only. Granular finish.

Pavetuf Jointing Compound – Not suitable for porcelain constructions laid on concrete sub bases, it is essential the product installation guide is followed when considered for use. Suitable for joint widths of 5mm to 20mm, with minimum 20mm depth required, joints must be struck off to ensure good compaction when installed with porcelain paving. Suitable for pedestrian use only. External use only. Granular finish.

-

One of the main advantages of Vitripiazza is its low maintenance properties and high stain resistance. Due to its technical properties and its very low porosity means that spills and soiling will not stain nearly as easily as other paving products. However, to keep it looking ‘as new’ some looking after may still be required.

- Brush the area regularly with a normal bristle brush to keep it clear of leaves and debris.

- General soiling can be easily washed off by using Pavetuf Porcelain Cleaner or with hot soapy water.

- For more heavy duty cleaning our Pavetuf range of specialist cleaners has been designed to deal with almost everything you will come up against.

- Algae or organic growth can easily be treated with Pavetuf Green-off.

- Pressure washers can be used by selecting the fan setting on the nozzle and ensuring a distance of approximately 30cm-45cm away from the surface is maintained so the jointing is not affected.

For further information see our Guide to Understanding Vitripiazza.

-

It's good practice to maintain areas where leaves fall be regularly brushing them up, as some leaves and plant life will leach tannins when they lay on the ground that can discolour paving and standing water. Do not worry though, if you have any paving where the leaves have left stains, our Pavetuf Green-Off Cleaner is the perfect choice to remove these easily. Green-Off is simple to apply and works very quickly to remove staining from the effected paving areas. It contains no solvents, acids or caustic soda, meaning it will not damage the treated surface and is safe to use on all natural stone, including sandstone and limestone, granite, marble, porcelain, ceramic and any kind of concrete and decorative paving.

-

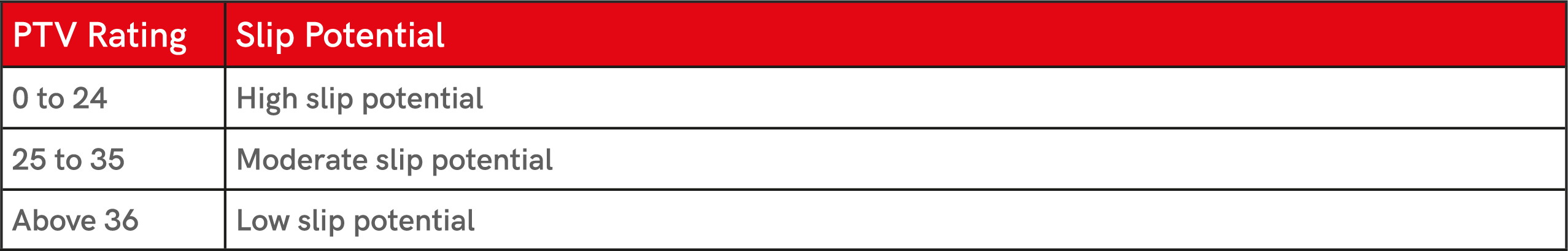

Every range of our Vitripiazza porcelain is categorised as low potential for slip, whether wet or dry and each range has a Declaration of Performance clearly stating the slip resistance rating.

All external porcelain slabs are tested under EN 14411 standard for slip resistance. There are two main recognised ways the tests are done, the Ramp test giving a “R” rating and the Pendulum test giving a “PTV” (Pendulum Test Value) rating. In Europe the Ramp testing is more commonly used but in the UK the Health & Safety Executive (HSE) has a preference for the Pendulum Test and is generally accepted to be the most reliable method of testing.

Not all porcelain is suitable for external use and the “R” and “PTV” rating may seem a little confusing so here is a broad view to help you understand these:

-

Ceramic tiles can be used for indoor and outdoor renovation projects but vitrified porcelain is the preferred option. So why is vitrified porcelain the preferred option and what are the differences between porcelain and ceramic?

The main difference between a vitrified porcelain and a ceramic tile is the water absorbency rate. Vitrified porcelain absorbs less than 0.5% of water whilst ceramic will absorb much more.

Vitrified porcelain paving is produced through the vitrification of its component materials, i.e., clays, feldspar and siliceous sands. These materials are sintered through firing in kilns in excess of 1200ºC, compacting the elements which closes the pores and giving the porcelain its excellent technical properties that enable it to be the perfect paving and cladding choice for many domestic and commercial projects.

Ceramic on the other hand is manufactured in a similar way but tend to not have the quality clay used in vitrified porcelain and are not fired at the same high temperatures. They then simply have a glazed top surface meaning they are not as hard wearing as vitrified porcelain.

-

The answer to this is yes. Our Full-Bodied ranges can be used for driveway products for trafficking with domestic cars or light vans but they will require installing on an adequate concrete base (minimum 100mm) and supporting sub-base and construction.

The paving should then be bonded to the concrete base using a high-performance cementitious tile adhesive appropriate for this type of traffic. Talasey are unable to give specific adhesive recommendations so seek guidance from the adhesive manufacturer for specific advice. The Colour-Bodied ranges are not recommended for driveway use.

-

Our Vitripiazza porcelain paving is available to purchase through our extensive network of distributors and stockists. To find your nearest stockist, please contact us.

-

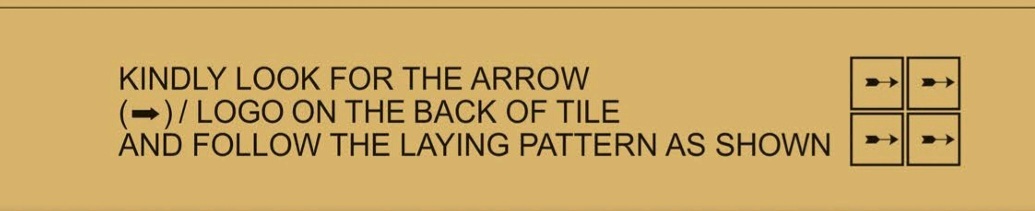

The arrow is pressed onto the tiles during manufacturing. It is a guide for loading the tiles into the kiln for firing and determines the directional pattern during the printing process. These arrows can be used when installing the tiles to give a better appearance.

If the tiles are laid keeping arrows in any one direction a more consistence pattern can be achieved. This is not mandatory, and tiles can be laid randomly if desired.

Vitripiazza ranges that the arrows will appear on:

- Anno

- Bellezza Lite

- Cava Quartz

- Cava Stone

- Cava Granito

- Sofia